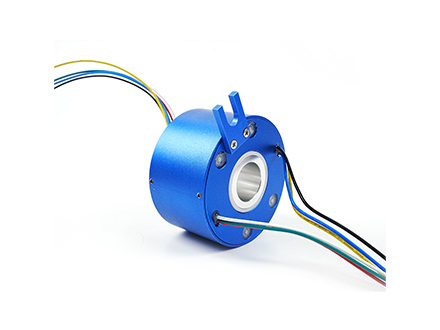

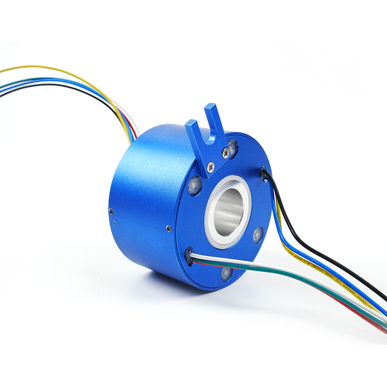

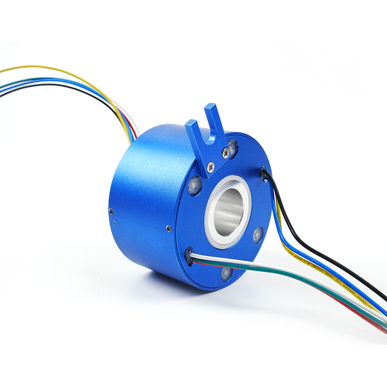

Descripción general del producto

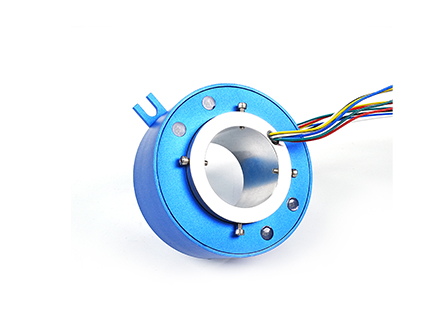

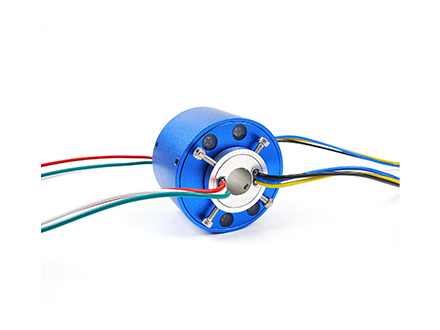

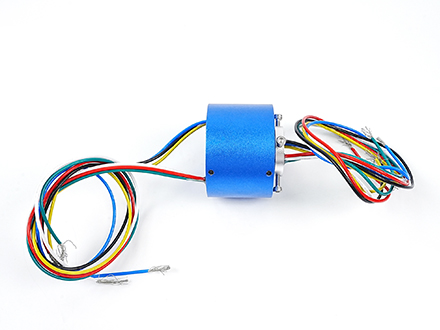

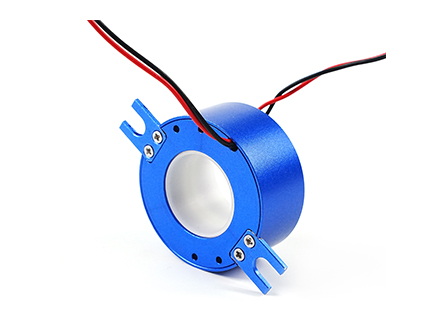

El de Reehonde Anillos de deslizamiento eléctricos ofrecen un rendimiento inigualable para una transmisión eléctrica y de datos continua y suave en equipos rotativos. Diseñados para diversas aplicaciones industriales, nuestros anillos deslizantes aseguran la transferencia ininterrumpida de energía y señal a través de interfaces rotativas, incluyendo robótica, sistemas de automatización, turbinas eólicas, dispositivos médicos y más. Ofrecemos soluciones de alta calidad, diseñadas a medida que satisfagan las demandas específicas de su proyecto, garantizando una funcionalidad y longevidad óptimas.

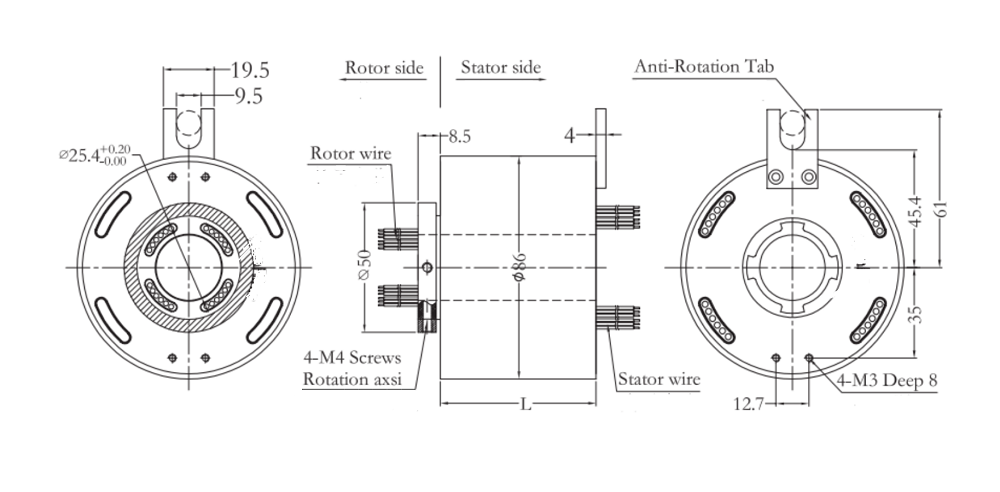

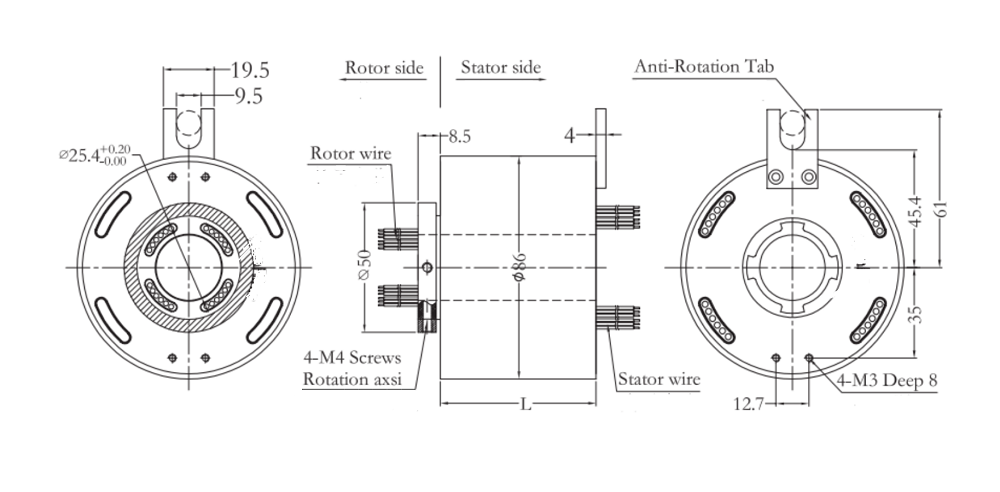

Parámetros del producto

Trabajo y vida | Consulte la tabla de selección del grado del producto |

| Potencia | Señal |

Velocidad nominal | Consulte la tabla de selección del grado del producto | Tensión nominal | 0 ~ 240VAC / CC | 0 ~ 240VAC / CC |

Temperatura de trabajo | -30 ~ C-80 "C | Resistencia al aislamiento | > 500MQ / 500VDC | > 500MQ / 500VDC |

Temperatura de trabajo | 0 ~ 85% RXH | Especificación del alambre | AWG26# Teflón plateado | AWG26# Teflón plateado |

Material de contacto | Consulte la tabla de selección del grado del producto | Longitud del cable | Longitud estándar 300mm (ajustable a petición) |

Material de la carcasa | Aleación de aluminio | Resistencia de aislamiento | 500VAC@50XHz Los 60 |

Torque de rotación | 0.05N.m + 0.02N.m / 6 carretera | Valor de cambio de resistencia dinámica | <0.01ω<> |

Protection level | IP51 |

|

|

|

Key Features

Customizable Designs: Our electrical slip rings are fully customizable to fit your unique application. Whether you require a specific size, shape, or specialized connection types, Reehonde’s team of engineers will work closely with you to create the ideal solution tailored to your specifications.

Multi-Channel Transmission: Each slip ring is designed to handle multiple channels for simultaneous transmission of power, data, and signals. With configurations that include power, coaxial, Ethernet, and fiber optics, we can accommodate a wide range of communication needs.

High Durability and Longevity: Our slip rings are built for extreme environments, engineered to last even in the harshest conditions. With superior materials and construction techniques, they offer exceptional wear resistance, high temperature tolerance, and protection against dust, moisture, and vibration.

Low Electrical Noise and Interference: Reehonde slip rings are designed to minimize electrical noise and interference, ensuring the stability of your system’s signal integrity. This is crucial for applications requiring precise data transmission, such as medical equipment and industrial machinery.

Compact and Efficient Design: With a focus on space-saving design, Reehonde slip rings are compact, lightweight, and easy to integrate into your equipment. Their efficient performance helps reduce the overall size of your system while maintaining high transmission quality.

Temperature Resistance: Our slip rings are capable of operating in extreme temperature ranges, from -40°C to 200°C, making them ideal for applications in industries such as aerospace, defense, and energy.

Sealed Protection: Many of our models feature sealed enclosures that provide IP ratings for dust and water protection, ensuring your slip ring continues to perform reliably in challenging conditions.

Smooth Rotation: Thanks to our precision manufacturing, Reehonde slip rings ensure smooth and continuous rotation, preventing wear and tear and reducing downtime due to maintenance issues.

Applications

Industrial Automation: Potencia and signal transmission in rotating machinery, robotic arms, and automated production lines.

Wind Turbines: Reliable electrical and data transmission for wind turbine generators, critical for maintaining efficiency in renewable energy applications.

Medical Devices: Continuous transmission of signals and power in medical imaging equipment, endoscopic systems, and patient monitoring systems.

Aerospace and Defense: Ensuring stable power and signal delivery in systems subjected to extreme conditions.

Offshore Equipment: Suitable for equipment operating in harsh marine environments.

Entertainment and Stage Equipment: Potencia and signal management for rotating cameras, lighting, and other stage equipment.

Company Strength

Reehonde is a leader in custom slip ring solutions, with over 20 years of experience in the field. Our expertise in precision engineering, combined with a commitment to quality, allows us to deliver products that meet the highest standards of performance. We collaborate with businesses across diverse industries, providing tailored solutions that improve operational efficiency, enhance system reliability, and ensure long-term durability.

Advanced Manufacturing Capabilities: Our state-of-the-art facilities and experienced engineers enable us to design, prototype, and produce high-quality slip rings tailored to your specific needs.

Global Presence: Reehonde’s products serve clients around the world, and we are committed to delivering exceptional customer service and support to businesses across various sectors.

Quality Assurance: All of our products undergo rigorous testing and quality control to ensure they meet industry standards and perform reliably under all conditions.

Installation Instructions

Preparation:

Ensure that the slip ring is compatible with your application’s voltage, current, and data transmission requirements.

Thoroughly clean the installation area to avoid contamination and damage to the slip ring.

Identify the correct wiring for power, signals, and data channels based on the configuration.

Mounting:

Install the slip ring in a location that allows free rotation without obstruction.

Use the provided mounting brackets or adapters to secure the slip ring to the rotating part of your equipment, ensuring it remains aligned during operation.

For some models, additional sealing may be required to maintain IP ratings, especially in outdoor or harsh environments.

Electrical Connections:

Connect the appropriate wiring to the terminals or connectors on the slip ring, following the electrical schematics provided in the product manual.

Use high-quality connectors and ensure all connections are securely tightened to avoid loose contacts during rotation.

Double-check all connections for proper insulation to prevent short circuits or signal interference.

Test:

Once installed, perform a functionality test by rotating the slip ring and verifying that power and signals are transmitted without interruption.

Monitor the slip ring during initial operation to ensure smooth rotation and correct performance.

Usage Precautions

Avoid Overload: Ensure that the electrical load does not exceed the rated capacity of the slip ring. Overloading can lead to overheating and premature failure.

Regular Maintenance: Regularly check for signs of wear or damage. Inspect the electrical connections and ensure they are securely tightened. Clean the slip ring periodically to remove dust, dirt, and moisture.

Temperature Monitoring: Ensure the operating environment remains within the recommended temperature range. Extreme heat or cold can impact the performance and lifespan of the slip ring.

Avoid Excessive Vibration: Excessive vibrations can cause wear and affect the smooth operation of the slip ring. Install vibration-dampening solutions if needed.

Proper Sealing: If using a slip ring in an environment prone to dust or water exposure, ensure that the sealing system remains intact. Replace seals if damaged to maintain the IP rating.

Reehonde’s Anillos de deslizamiento eléctricos offer a comprehensive solution for your power and data transmission needs. With customizable options, high durability, and precision engineering, our slip rings are the perfect choice for industries requiring reliable, long-lasting performance in rotating equipment. Whether you are looking for a standard model or a custom-engineered solution, Reehonde has the expertise and experience to meet your requirements.